Cooking with Woodgas

Basics | Policy Advice | Planning | Designing and Implementing (ICS Supply)| Technologies and Practices | Designing and Implementing (Woodfuel Supply)| Climate Change

Introduction

The use of woodgas is one option to use the biomass energy in a very clean and efficient way. In order to use woodgas for cooking, so called “Gasifiers” or “Micro-gasifiers” have been developed.

How is Woodgas Created?

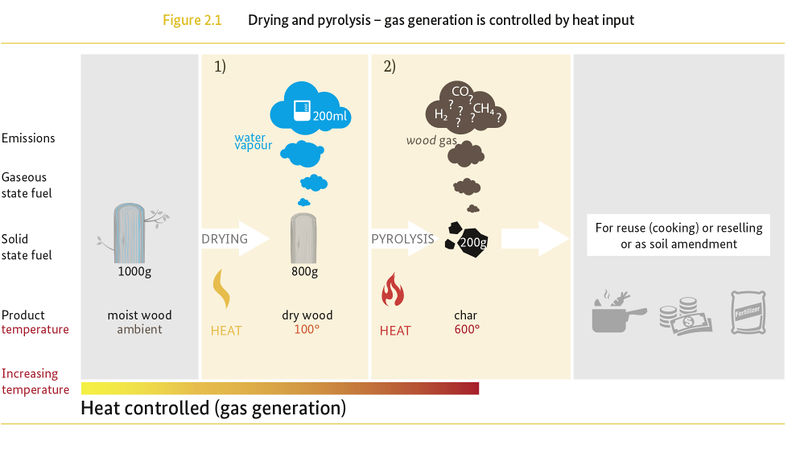

Combustible woodgas is generated by pyrolysis, which requires a temperature of over 300°C. Mostly this “external” heat is initially provided by a lighting material, such as kerosene or a match. First of all, with increasing temperature at around 100° C, the moisture excesses in the form of water vapour. Excess moisture evaporates into the atmosphere and leaves a solid dry biomass behind. At temperatures beyond 300° C, biomass starts to pyrolysis (‘break apart by fire’). Increased temperatures eventually cause a complete conversion of the biomass into volatile vapours and a solid residue called char. The vapours contain various carbon compounds with fuel value, referred to as ‘woodgas’. Being that the solid by-product of this process is char, mostly composed of pure carbon, the process is also termed ‘carbonisation’.[1] Drying and pyrolysis are processes that consume heat and do not create any useful surplus of heat. Using air-dried fuel (moisture content of 10% – 20%) is recommended in order to shorten the drying time and reduce the required heat input. The figure below shows both processes. In each step, vapours are released and the remaining solids decrease in mass and volume. At temperatures of 600° C, the pyrolysis process converts the dry wood into combustible ‘wood-gas’ and solid char.

The char can be used in conventional or improved charcoal cookstoves, or as biochar by adding it to the soil as a fertilizer.

The combustible woodgas contains energy-rich vapours and gases. During the woodgas combustion these gases react with oxygen, which is provided via secondary air. The thoroughly mixed freshly generated hot woodgas and the oxygen are then easily ignited by a spark or by heat. Woodgas combustion leads to the creation of carbon dioxide, water vapour, heat and light. Ideally, only fully oxidised gases, without unreleased energetic value, escape the combustion zone – meaning that all woodgas has been oxidised into carbon dioxide and water vapour.

Biomass Sources for the Generation of Woodgas

The variety, ‘unpredictability’ and inconsistency of natural solid biomass are the primary challenges for clean combustion in a cook stove. If solid biomass is converted into a predictable fuel such as woodchips, briquettes or pellets and burned in a gasifier cook stove, emissions can be compared with the burning of LPG.[1] In order to enable an equal movement of the pyrolysis front in the gasifier and to prevent blockages, more or less uniform fuel is best suited for micro-gasifiers. Standardised or processed fuels, such as woodchips, pellets or briquettes, make the performance of the fuel more reliable.

The solid biomass fuel should have the following features to achieve optimal fuel use and combustion efficiency:[1]

- Be dry: with moisture content preferably below 20%. High moisture contents result in less stable stove operation and decrease the available energy output of the fuel since more energy is needed to evaporate the moisture.

- Be slightly chunky to allow for air/gas passage: particle size should exceed 4 mm. For finer feedstock, like sawdust and rice husk, it is advisable to use a fan-powered micro-gasifier with forced convection to enhance and control the flow of air.

- Have particle shapes that enable convenient loading of fuel into the container. This includes easy stacking and the ability to easily pour fuel chunks into the container.

- Have relatively uniform particle size distribution to avoid compacted zones or oversized voids within the fuel container that could prevent the uniform progression of the pyrolytic front through the fuel-bed.

- Have sufficient energy density in order to balance heat output of the ‘burnable mass’ (inside a given fuel-container volume) with cooking duration and refuelling efforts.

Multi-purpose plants are ideal resources for fuelling gasifier cookstoves. There are numerous examples of such plants that develop woody or fibrous stems with optimal fuel properties; these include pigeon peas, millets, flax, sesame, moringa, castor, jatropha, sesbania, tephrosia, bamboo, switchgrass and miscanthus. The development of micro-gasification, the research on local feasible biomass feedstock and the adoption of micro-gasifiers are relatively new in the cooking energy sector. It is still at an early stage of development.

There are several projects that direct their activities into fuel production options combined with micro-gasifier dissemination:

- Emerging solution focusing on improved processed biomass fuel and combine the dissemination in combination with the appropriate stove in Zambia. www.emerging.se

- Inyenyeri, a Rwandan Social Benefit Company, operates in Rwanda and plans to become the largest pellet supplier in East Africa http://inyenyeri.org

- Niger: Aaron stove http://www.proener.unito.it/relazioni/rapport_fourneau_Aaron.pdf

- In Senegal, the local rice company, CNT, and GIZ are experimenting with different processing options for Typha grass, rice husk and rice straw.

Further Information

Related article on energypedia

- Gasifier Stoves, article on energypedia

- Micro-Gasifiers, article on energypedia

- Small-scale Biomass Gasification, article on energypedia

- Micro-gasification: Cooking with Gas from Dry Biomass by Christa Roth (2014) provides a great overview on the gasification process itself, solid biomass feedstock for gasifiers and their processing, an overview on micro-gasification diversity and an outlook on the use of biochar.

- A compilation of micro-gasification publications by Paul Anderson (Dr. TLUD)

- Micro-Gasification: What it is and why it works by Anderson, P. et al. in Boiling Point, 53 issue (2007)

- Microgasification cookstoves and pellet fuels from waste biomass: A cost and performance comparison with charcoal and natural gas in Tanzania by Lotter, D. et al (2015)

References

This article was originally published by GIZ HERA. It is basically based on experiences, lessons learned and information gathered by GIZ cook stove projects. You can find more information about the authors and experts of the original “Cooking Energy Compendium” in the Imprint.

- ↑ 1.0 1.1 1.2 Roth, C. (2014): Micro-gasification: Cooking with Gas from Dry Biomass https://energypedia.info/images/0/05/Micro_Gasification_2.0_Cooking_with_gas_from_dry_biomass.pdf

top of page