Low-Cost Polyethylene Tube Digester

Overview

There are different types of small scale biogas digesters. Some of the biogas digesters are summarized below:

The table below gives a first comparision of the different types.

Factors |

Fixed dome |

Floating drum |

Tubular design |

Plastic containers |

|---|---|---|---|---|

Gas storage |

Internal Gas storage up to 20 m³ (large) |

Internal Gas storage drum size (small) |

Internal eventually external plastic bags |

Internal Gas storage drum sizes (small) |

Gas pressure |

Between 60 and 120 mbar |

Upto 20 mbar |

Low, around 2 mbar |

Low around 2mbar |

Skills of contractor |

High; masonry, plumbing |

High; masonry, plumbing, welding |

Medium; plumbing |

Low; plumbing |

Availability of Material |

yes |

yes |

yes |

yes |

Durability |

Very high >20 years |

High; drum is weakness |

Medium; Depending on chosen liner |

Medium

|

Agitation |

Self agitated by Biogas pressure |

Manual steering |

Not possible; plug flow type |

Evtl Manual steering |

Sizing |

6 to 124 m³ digester vol |

Up to 20 m³ |

Combination possible |

Up to 6 m³ digester vol |

Methane emission |

High |

Medium |

Low |

Medium |

Low-Cost Polyethylen Tube Digester

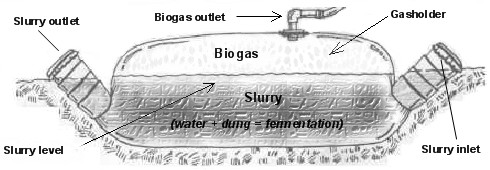

In the case of the Low-Cost Polyethylene Tube Digester model which is applied in Bolivia (Peru, Ecuador, Colombia, Centro America and Mexico), the tubular polyethylene film (two coats of 300 microns) is bended at each end around a 6 inch PVC drainpipe and is wound with rubber strap of recycled tire-tubes. With this system a hermetic isolated tank is obtained (figure td1 ).

| One of the 6" PVC drainpipes serves as inlet and the other one as the outlet of the slurry. In the tube digester finally, a hydraulic level is set up by itself, so that as much quantity of added prime matter (the mix of dung and water) as quantity of fertilizer leave by the outlet. Because the tubular polyethylene is flexible, it is necessary to construct a "cradle" which will accommodate the reaction tank, so that a trench is excavated (picture td3). | ||

Gasholder and Gas Storage Reservoir

The capacity of the gasholder corresponds to 1/4 of the total capacity of the reaction tube (figure td1). To overcome the problem of low gas flow rates, two 200 microns tubular polyethylene reservoirs are installed close to the kitchen, which gives a 1,3 m³ additional gas storage (picture td4).

To contrast these simple biogas plants, figure 2 gives an impression about dimensions of industrial plants which are, for example, built in Europe.

Installation Manual for Low Cost Polyethylene Biogas Digester

Experience with Polythylene Biogas Digester (PBD)

To read about the experiences of deploying Polyethylene biogas digester, please see the article on