SPIS Toolbox - Establish and Refine Maintenance Plan

| ►Back to the Start Page | ►Back to the Module Page | ►Go to the Next Chapter |

1. Establish and Refine Maintenance Plan

After installation of the system an operations manual should be handed over to the producer (see SET UP Module) by the technology supplier, or service provider. The operations manual includes instructions for operation, maintenance and troubleshooting, along with the contact details of the service provider. Based on this, the service provider and producer should develop a maintenance plan. The producer and the agricultural advisor should revise the maintenance plan regularly.

Checklists are helpful tools to ensure that maintenance is done regularly and properly. For this, the SPIS toolbox has been developed with checklists on the proper maintenance of the PV generator and the irrigation system. The following aspects are important for each of the main components of an SPIS:

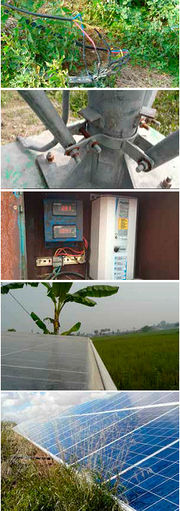

- Water source and pump: Solar pumps generally do not need a lot of maintenance if used in clean water, free of sand, sediments or aquatic plant growth. The water source therefore needs to be kept clean. Under these conditions pumps can last up to 10 years.

- Solar panels and mounting structure: Solar panels and their mounting structure generally require very little maintenance since there are no moving parts. Panels need to be kept clean and free of shade however, while the mounting structures should be stable. The PV array should be protected from animals and falling objects. Well cared for solar panels and mounting structures last up to 20 years.

- Electronics and controls: As controllers/inverters are sensitive to overheating, they have to be installed in a place where faultless operation is guaranteed. Factors to be considered include the ambient temperature, the heat dissipation capability (ventilation) and the relative humidity. For service and maintenance purposes, the controller should be easily accessible. Furthermore, there has to be a circuit breaker between the PV generator and the controller. Insects and small animals, such as lizards, like to build their nests in junction boxes and may destroy electronic components (e.g. by formic acid). Proper sealing of all openings (e.g. with cable glands) is essential.

- Irrigation System: If drip irrigation is applied, the water must be filtered because the drip emitters can clog easily. Depending on the sediment load of the water, the filters must be cleaned regularly – this can be up to several times a day. This requires a certain level of technical knowledge and skills. In addition, the drip lines must be flushed regularly and the drip elements must be examined for blockages and replaced if necessary. The SPIS tool MAINTAIN – Water Application Uniformity Guide is applied to check the uniformity of water distribution in a drip irrigation system. The test is part of the system acceptance (see module SET UP) but is also part of a routine check. It should also be considered that for hard water (irrigation water with high dissolved lime concentrations), scaling up and clogging of pipes will occur if pipes are exposed to heat (direct sunshine).

On the next page an overview of common failures from the field and the associated fixes are given.

Example of Common Installation Mistakes

Outcome/Product

- Maintenance plan;

- MAINTAIN – Maintenance Checklist;

- MAINTAIN – Water Application Uniformity Guide.

Data Requirements

- Instructions on proper maintenance of each component of the SPIS;

- Checklist on water analysis.

People/Stakeholders

- Producers / producer groups;

- Agricultural advisors;

- Technology and service providers (electricians, companies providing PV systems).

Important Issues

- Regular maintenance is indispensable for efficient and long term operation of any pumping and irrigation system.

- An SPIS is reliable and maintenance costs are low if maintained adequately.

- Maintenance plans should be reviewed regularly together with the technology/service provider and the agricultural advisor.

| ►Back to the Start Page | ►Back to the Module Page | ►Go to the Next Chapter |